“Half the size of a paper clip, weighing less than a tenth of a gram, it leapt a few inches, hovered for a moment on fragile, flapping wings, and then sped along a preset route through the air.” This was the commentary coming out of a lab in the Harvard School of Engineering and Applied Science (SEAS), as Caroline Perry covered the first flight of the RoboBee.

The RoboBee just happened to be the first time a mechanized/robotic insect was flown according to a set of criteria and rules. This landmark incident—which was built on the back of approximately a 10 year research done by combined designers and engineers from the SEAS and the Wyss Institute for Biological Inspired Engineering—highlighted the possibilities in which combining CAD design and robotics can change the ways we operate.

Understanding the Aesthetics of the RoboBee

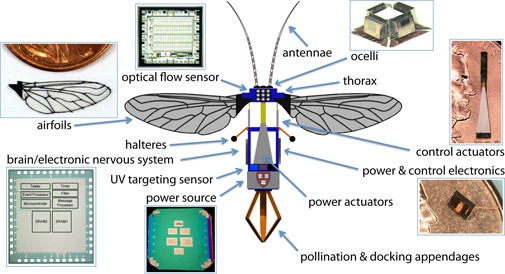

Since the inception of the RoboBee program, the aim was to use science to achieve a perfect imitation of nature and the subject in this case was the Bee. The idea was to design a robotic insect which closely mirrored a natural insect in terms of size and movement.

The team of engineers faced cutting edge challenges such as; developing microscopic flight muscles that function in a realistic manner, understand flight dynamics in relation to air currents, the mechanism the RoboBee has to operate with etc.

The solutions to these problems where developed from scratch—according to Kevin Y. Ma, a student of SEAS. The microscopic wings where designed using piezoelectric Actuators, which are ceramic strips that react to an electric field, Carbon fiber as the material of choice for the joints of RoboBee, computer-aided design software was used to model/simulate prototypes of certain parts and movements, the pop-up manufacturing technique was employed to assemble all the miniature layers together to create the RoboBee.

The Role of Computer Aided Design in the Development Process

Developing robotic insects, requires diverse procedures which range from programming to designing prototypes that effectively show the simulations between mechanized parts and how they function. This processes required an intensive study of the anatomy of a real insect, as well as studying its movement patterns.

This research was followed by the creation of a model designed to meet the aesthetic specifications of the wings of a real-life insect while also illustrating the complex technical procedures required to precisely assemble each part, and how they will be fitted for the final stage of the design process.

CAD technology helped the team design a working prototype structure for the RoboBee which was used for illustrations and simulations for stress analysis and to trouble shoot problematic areas. These simulations helped to improve the overall alignment of the robotic system.

The success experienced by the engineers at Harvard’s SEAS has been hailed as a milestone in the field of robotics and according to the design team, “the more prototypes developed, the more experienced engineers will become in designing microscopic robotic insects.

– The CAD Chief

IndiaCADworks