BIM Implementation – Progressing from BIM 3D to 7D

There’s little doubt that the construction industry will benefit greatly from BIM technology. There are literally dozens of advantages that accurate, detailed 3D models of building projects bring. The key thing to understand is that BIM is more than just a CAD model. It’s more like a database that stores design, construction, and maintenance information, as well as any additional data related to the project.

The main benefit of BIM is the cost saving, both in the short-term and over the long-term of a project. The short-term cost savings are readily apparent – improved workflows, fewer clashes, streamlined scheduling, an easier reworking of designs, etc.

The longer-term cost benefits aren’t always so obvious. It requires a shift of focus from the initial capital outlay of a construction project to a bird’s eye view of the entire project covering the whole life-span. For instance, using BIM models to enhance collaboration between different construction contractors will simultaneously speed up the delivery of the project and increase the build quality. This will also have a positive effect on the long-term maintenance of the asset.

So, how can these benefits be realized in real life?

Is it simply a case of building a high-quality BIM model, including mechanical, electrical and plumbing details, and making it available to all construction parties? Or, is there more to it?

Before looking at the current BIM picture and the different levels of implementation, it’s useful to understand how BIM technology has developed and progressed over the years.

The Evolution of BIM

Although BIM has been available in various forms for decades, it is only in the last seven years or so that it has started to generate real interest in the construction industry. This is mainly because computing technology is now at a stage where it can handle the complexity of a detailed BIM design and yield the cost and efficiency benefits mentioned earlier.

-

1963

The early days of BIM date all the way back to the 60’s with the advent of Computer Aided Design (CAD) software.

-

1975

A prototype known as Building Description System (BDS) was presented that laid the foundations for BIM as we know it.

-

1977

GLIDE (Graphical Language for Interactive Design) was created which had many of the features included in modern BIM systems. These early versions of BIM were very basic but enabled more efficient prefab construction

-

1977

A BIM platform known as RUCAPS (Really Universal Computer-Aided Production System) was used to for the prefab renovation of Terminal 3 at Heathrow Airport.

-

1980 & 90

saw pioneering software such as ArchiCAD take things further towards virtual 3D design and construction.

-

2000

Revit was born.

-

2001

Navisworks released.

Revit and Navisworks platforms have taken BIM to a new level of sophistication, especially since both companies were bought by Autodesk in 2002 and 2007 respectively. BIM has progressed over the interceding years, from a purely structural design tool to a multi-purpose, cross-disciplinary resource that assists with more than just piecing together prefab elements.

The increased complexity of BIM has led to the recognition of several different levels of BIM implementation. These range from 3D to 7D. Here is a brief outline of the criteria for each BIM level, which will be expanded upon later in this article:

-

A 3D rendered CAD representation of the various construction elements.

A 3D rendered CAD representation of the various construction elements. -

3D BIM + linked construction schedule information.

3D BIM + linked construction schedule information. -

3D BIM + schedule information + cost estimation.

3D BIM + schedule information + cost estimation. -

Includes energy simulation and analysis.

Includes energy simulation and analysis. -

Includes post-construction information such as asset condition and maintenance requirements.

Includes post-construction information such as asset condition and maintenance requirements.

The Need for BIM in the Construction Industry

The increased sophistication of CAD and BIM technology has coincided with growing challenges in the construction industry. The following challenges have led to widespread interest in BIM adoption:

70% of contractors admit that they struggle to find enough skilled tradespeople or qualified engineering professionals to meet growing demand. 47% of these contractors say that this could lead to safety issues as they will have to rely on unqualified or under-skilled staff. BIM can help to ease some of these concerns as the higher levels of information conveyed in a BIM model means that workers won’t need to rely so much on prior knowledge and experience to solve problems on site. Safety concerns can also be alleviated to a degree, as the BIM model will highlight clashes, hazards and other potential problems such as site overcrowding.

As more millennials enter the workforce, they have a very different outlook and skill-set to previous generations. Most people under the age of 30 are skilled, or at least competent, in using technology. By adopting BIM technology, conflicts between senior and junior engineers can be resolved, as they can combine skills to assist each other.

Technology has transformed most aspects of modern life, and construction is no exception. Companies that don’t keep up with the changes will find themselves left behind the competition. The pressure created by these rapid changes can divide workforces and managers, and if the technology isn’t implemented well, it can complicate workflows. Therefore, it is best to take a gradual approach when implementing new technology to avoid ‘upsetting the applecart’ too much.

BIM is ideal for this because, as mentioned earlier, there are several levels of implementation that can be undertaken gradually. Construction companies will gain immediate benefits from implementing 3D BIM and can slowly progress through the levels when appropriate.

As more and more engineering graduates come through with university experience of BIM, the technology can be used to greater levels of sophistication, and the full advantages realized.

It’s estimated that the construction industry produces between 25-40% of global carbon emissions. Pressure from governments around the world means that construction companies are looking to reduce their environmental impact and move towards sustainable methods. BIM is ideal for improving sustainability as it can help to design more energy efficient buildings and reduce waste.

Last, but not least is the issue of design and build complexity. New building techniques, tools, and resources are used with greater frequency every day. Combined with the lack of skilled staff mentioned earlier, this can have dire consequences for delivering projects on time and within budget. Research shows that only 30% of companies deliver projects within budget and half that amount deliver on time.

Fortunately, BIM can help to reduce the complexity, or at least simplify the way design information is presented. The resulting cost and efficiency benefits of BIM are needed now more than ever.

BIM Progression From 3D to 7D

3D BIM

A three-dimensional model is created using a BIM CAD platform such as Autodesk Revit. The model contains not just the 3D rendered representation of the building, but also information relevant to the designers, contractors, project managers, investors and project clients. It can be presented in many ways and used for in-depth analysis of different aspects of the design.

The BIM model often contains architectural, mechanical, electrical and plumbing information, as well as other relevant data and information. Therefore, the BIM model encourages greater cross-discipline collaboration, clash detection, and analysis of structural or logistical problems. If changes are needed after the design phase, the level of reworking is minimized when using a BIM model compared to traditional CAD methods.

The 3D BIM model is dynamic and can be updated with new data throughout the construction process and beyond. This makes it a powerful tool for predictive modeling, allowing the resolution of potential problems ahead of time.

Summary of BIM 3D benefits:

-

01Improved project visualization

-

02Improved collaboration

-

03Less reworking of designs

4D BIM

The 4D level of BIM includes time-related information in addition to the 3D CAD model. A 4D BIM model links elements or components of the design with the construction schedule, meaning that a visualization of the sequence of events can be displayed. The linked schedule can cover the entire project, from investment to completion.

4D delivers powerful insights into the way the project elements fit together leading to more effective planning and management. A 4D-prepared BIM model highlights potential schedule conflicts before they happen, giving project managers more time to adjust the schedule in advance. 4D also creates more opportunity to mitigate risks and hazards and supports more effective communication between all the different parties involved in the construction process.

Summary of BIM 4D benefits:

-

01Optimized planning process

-

02Improved fabrication and logistics

-

03Improved coordination of site activities

5D BIM

5D BIM includes cost information built-in to the model. It is useful for cost estimates, analysis and budget tracking. This means that during the design stage, consideration can be given to both scheduling and cost implications of certain design decisions. This will help to keep costs minimized, or balanced, right from the outset of the project.

The increased accuracy of projected costs helps investors and contractors alike. The 5D BIM model can also be used to predict parts of the project that may be prone to scope changes, overruns or changes in workforce requirement, and mitigation plans can be drawn up in advance. This efficient approach to planning will reduce costs and improve the flow of the project.

Summary of BIM 5D benefits:

-

01More accurate budgets and cost analysis

-

02More efficient planning

-

03Overall cost reduction

6D BIM

6D helps to address the sustainability issues facing the construction industry by allowing more accurate energy analysis and calculations. Designers can adjust the layout or service positioning to minimize energy loss and wastage.

During the construction phase and the lifecycle of the building, real-time data can be added to the model and analyzed which helps to verify the initial estimates. In other words, the more data that is measured and validated, the more accurate future analysis will become.

Summary of BIM 6D benefits:

-

01Reduction in energy consumption

-

02Improved energy analysis

-

03More sustainable design methods and models

7D BIM

The final level of BIM implementation covers the final stages and overall lifecycle of building projects. Project managers and asset owners can add and extract data from the BIM model. Information such as building or element condition, technical specs, maintenance schedules, technical reviews, equipment manuals and warranty details can easily be stored and viewed at a later date.

This fully integrated approach to data storage and retrieval expedites the process and makes it more efficient for years to come. For instance, if supplier details are linked to building elements, replacement parts can be quickly identified and ordered without expert assistance.

Summary of BIM 7D benefits:

-

01Easy storage and retrieval of all information and documentation related to the project

-

02Improved and more efficient asset management

-

03Increased lifespan of the asset

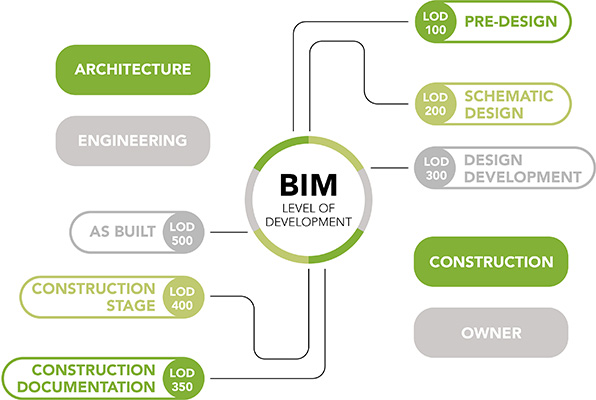

Lifecycle BIM – LOD 100 to 500

This section will give an overview of the way a model changes throughout the lifecycle of a project and which parties are responsible at each stage. The stage of a construction project BIM model can be defined by the following Levels Of Development (LOD):

-

LOD 100

Initial ConceptAt this stage, the BIM model is no more than a basic representation of the physical properties of the design. Dimensions and measurements of area, volume and location are included. Surveyors are responsible for the accurate collection of survey data. Architects and designers are responsible for the creation of the model while liaising with the client to ensure that design requirements are met.

-

LOD 200

Schematic LayoutFurther definition is given to building elements with more precise size, shape and orientation details added. Non-geometric qualitative information can also be added. Architects and designers are responsible at this stage, with input from surveyors.

-

LOD 300

Detailed DesignAt this stage, the model includes specific assemblies, components, and detailed geometry. Accurate shop drawings are produced. Architects and designers collaborate with specialist suppliers to ensure assemblies are designed and modeled correctly. The design team may liaise with contractors to add scheduling information and cost estimates, etc.

-

LOD 350

Construction DocumentationBuilding elements are linked, and interfaces between various systems and services are added. The model is approaching a construction-ready stage. Architects and designers liaise with construction contractors to ensure accuracy.

-

LOD 400

Fabrication and Assembly-ready ModelAll fabrication and assembly information is added, with precise geometric and non-geometric information. The designers make the model fully available to suppliers and contractors.

-

LOD 500

As-built StageAs-built data is added to the model for operational use and maintenance. All modeled elements can be analyzed against design. At this stage, the contractors and asset owners are responsible for the maintenance and oversight of the BIM model.

-

Applications of BIM at Professional Level

Design Consultants – Architecture, Structural, MEP, and Landscape

The applications of BIM for design consultants are many. BIM software platforms such as Autodesk Revit, Autodesk Navisworks and Bentley’s suite of programs allow designers to build models by creating building elements or using libraries of elements (known as ‘families’).

BIM allows for a more collaborative design approach, with input from disciplines that have differing design briefs. With this approach, clashes can be detected early and rectified making the design process much smoother.

Although designers are mostly concerned with BIM levels 3D to 5D, the higher levels also benefit them as they can elicit feedback and collect data about the performance of the structure and use this to inform future design decisions.

Construction Contractors – Main and Specialized Subcontractors

Projects that implement BIM tend to use the model as the central focus. All relevant stakeholders in the project can use or amend the model as appropriate. For instance, contractors can add component information to help with future maintenance. If contractors need to raise change orders, they can send them directly to the architects through the model.

The information contained in the model is useful for most contractors involved in the actual building stage of the project and allows them to collaborate with each other far more effectively. Ideally, main contractors and subcontractors should be involved in the design process, with access to the model to allow them input into the preconstruction design decisions. This is especially important with 4D and 5D BIM where their hands-on experience can help to resolve scheduling and cost issues.

Business Owners – Developers, Project Managers, and Facility Managers

The primary purpose of BIM is the collection, collation, and management of information, both in graphical and text format. It’s more than just a design tool, and as such has managerial applications.

Depending on the project, the asset owners may be private developers, government bodies or project management teams, or may transition from one to another over time. Project managers will typically own the project until snagging is completed then hand it over to their clients. Therefore, the BIM model should be built and maintained with this in mind, providing all the information that current and future owners may need.

Project managers are also obliged to take an active role in the creation of the model, especially at levels 4D and 5D. They should also be responsible for inputting data until completion of the project and handover.

Facility managers can use the BIM model for improved management of space, reducing expenses and streamlining maintenance activities. BIM also saves a lot of time as it removes the need to manually populate separate facility management software as details of equipment location, user manuals, and technical information are already on-hand and can be directly exported to FM software.

Surveyors

Surveying agencies or contractors are sometimes overlooked in the BIM process, but they are integral to its success. A surveyor’s work is not necessarily complete upon handover of data. The BIM model relies on highly accurate data, and it also highlights where extra surveying may be required early on in the design process. Therefore, surveyors should be involved in the 3D conceptual modeling stage, being on hand to rectify survey errors or undertake extra surveying.

BIM Implementation Success Story

Kerr Hall East, Ryerson University, Canada

Kerr Hall East was constructed in the 1960s and required renovation. The building’s main functions are laboratories, classrooms, and office space. The original design and as-built drawings were unable to be found, and the hall had undergone several small-scale structural and plant renovations over the years.

The designers and project management team wanted to use BIM to the highest 7D level for this project. Here is a summary of how they achieved this:

-

01

Built the initial 3D BIM model using 2D CAD floor plans from a recent space audit that contained base geometry.

-

02

Added hazard mapping data, inventory tracking and asbestos mapping (4D)

-

03

Included project planning and schedule information (4D and 5D)

-

04

Added energy conservation estimates (6D)

-

05

Included location of maintenance equipment (7D)

The team faced some challenges along the way:

-

Data uncertainty

Surveyors conducted spot checks to verify CAD drawings. The percentage of spot checks where site elements didn’t tally with the drawings was used as the certainty rating. The designers only included items that had a certainty rating of over 50% in the model. All equipment schedules were flagged to highlight certainty.

-

Managing information transfer

Whenever information is transferred, there is potential for loss or corruption of data. Care was taken to ensure that “push” transfers of data from the BIM model to the FM system, and “pull” transfers in the opposite direction were managed correctly and data integrity maintained.

-

Controlling the progression from 3D to 7D BIM

As there was no digital information available at the beginning of the project, care had to be taken when building the initial 3D model. Building the model could not be rushed, and adding extra information to progress to 7D had to be carried out in carefully managed stages.

7D BIM Development Framework

The Way Forward for BIM

Although BIM is a relatively new technology in the construction industry, it is advancing at a breakneck pace. We are only just scratching the surface of what is possible with BIM.

For instance, Dutch contractors are currently trialing ‘8D BIM’ which involves a fully integrated project delivery that has the aim of delivering ‘zero-carbon’ housing. This is a huge leap regarding environmental sustainability and could, in time, become an industry standard for the housing market.

There’s no doubt that BIM technology will continue to progress in the coming years and innovative and boundary-pushing projects like the Dutch one mentioned above will help to drive things forward. How long before we see revolutionary technologies such as 3D printing and advanced robotics working in collaboration with BIM models?

Watch this space!

– IndiaCADworks

Disclaimer:All the product names, logos, trademarks, and brand names are the property of their respective owners. All the products, services, and organization names mentioned in this page are for identification purpose only and do not imply endorsement.