Digital Twin – the Best Way to Start a Building Project

Increasingly digital technologies are often associated with areas like computing, the Internet of Things devices, and other electronics, but the reality is that digitalization is revolutionizing every industry. The construction industry may not be the first area you think of when it comes to digitalization, but increasingly complex and technologically fine-tuned projects have brought about new technical challenges. And those technical challenges are more and more able to be solved with digital solutions. Digital twin technology is one such opportunity.

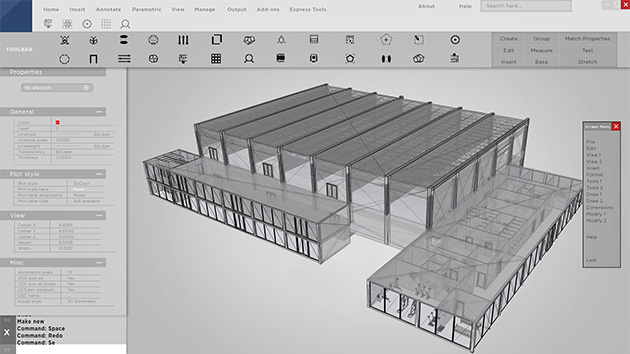

The use of digital twins has been at the fingertips of construction professionals for a while, with 2D and 3D models of buildings in CAD programs technically counting as a digital twin technology. But the expert and state of the art construction firms will take it much further, as digital twins can, when fully tapped into, give an entirely new direction to a building project.

What Is Digital Twin?

The digital twin technology is, simply put, a replica of a physical entity that lives entirely in a digital space. A digital twin could be a model of an electric power grid that simulations can run on, it can be a map-based representation of a government’s assets, or in the context of construction, it can be a digital representation of a building’s design, construction, and complex systems.

Embracing digital twin construction means that, for example, the electrical systems of a building are built first in a computer model, and then when it’s built-in actuality the digital twin model can be connected via the Internet of Things to the model and create a full digital twin smart building. Operating the digital twin can be used to manipulate the real-life systems in whatever way the building owner likes. These are the types of possibilities that can be unlocked with digital twin construction is prioritized.

How to Use Digital Twin for Project Design and Planning

While digital twin models can be built, kept, and updated after the physical construction, the most useful aspects of digital twin technologies can actually come during the project design and planning process. For an architecture or construction firm that’s building it’s next great building, the digital twin construction industry would encourage the following types of applications:

- Ensuring compatibility of complex building systems: When designing all of the complex inner workings of a building, such as electrical systems and plumbing and HVAC and fire sprinklers and more, much trouble can arise when these aren’t planned in conjunction with each other. Utilizing an advanced digital twin construction planning method allows for clashes in systems to be identified and rectified early in the planning.

- Planning for actual occupants: Taking this process a step further, while the complex systems may physically fit with each other, using a digital twin planning process will highlight issues in the practical use of the building, such as an electrical panel not being as accessible as it needs to be, inopportune compatibility of worker locations, and building maintenance needs.

- Retrofitting existing buildings: For buildings that get constructed using digital twin planning technology, retrofits needed later one becomes abundantly easier as architects and construction professionals can plan out what they want to do, uncover unexpected impacts of the remodeling process on building systems, and more.

How to Optimize a Construction Process Using Digital Twin

Digital twin buildings are not just made during the planning process, but these advanced technologies can really come in handy when it comes to the actual construction process.

- Construction timeline planning: For the construction professionals who will actually be putting the building together, the availability of digital twin models means that foremen and other construction leaders will be able to effectively plan out the construction process from start to finish to optimize manpower, efficiency in process, and more.

- Materials planning: Having an exact digital replica in a computer-simulated model also takes the guesswork out of determining how much of various materials and construction tools are needed, as the digital twin can convey that information exceedingly accurately.

- Worker scheduling: Having too many workers on site that cannot all be working simultaneously because of clashing needs or safety issues is a significant form of waste in the construction industry. But when the construction process can be planned out via digital twin technology, the process of who should be on-site and when is made extremely clear and efficient.

Digital Twin Applications in the Construction Site

Now that the design and construction process has been optimized thanks to the miracle of digital twins, you may think the digital twin applications are made. But you would be wrong, as on the construction site will be another key area of focus for the use of digital twin construction:

- Discrepancy monitoring: Oftentimes, the person leading construction day today on the construction site is not the same person who designed and planned the building, meaning intent can be misconstrued, and mistakes can be made. But with digital twin technology, construction leaders can get alerts about if something that’s been constructed is not in alignment with the original planned design in real-time, so mistakes can be caught and rectified as soon as possible.

- Progress tracking: Falling behind schedule is one of the quickest ways for a construction site to fall out of budget, but the digital twin building and construction can minimize the chances of this by providing live updates to those in charge about where construction is compared with where it needs to be to stay on schedule. This accountability can go a long way towards improving the construction process.

- Safety hazard identification: The power of the digital twin is so great that it can even monitor where and when the greatest safety hazards will arise in the construction process and ensure that all working on site are informed and know where and when to be the most cautious.

- Worker tracking: An active construction site can be akin to a beehive in how much it is buzzing with activity from different workers doing different roles. For any construction firm, keeping track of who is doing what and where each worker and necessary equipment is can be a logistical nightmare, but digital twin construction can even account for the human element of workers and make sure all are kept on track and accountable to their jobs.

How to Create a Digital Twin

If all of the above sounds appealing, digital twin construction may be the right process for your construction planning, designing, and implementation to take. Digital twin technology may be a complex topic, but with the right tools, the process is accessible to all:

- Choose the right digital twin construction software: Digital twins require the right tools for the part, so you’re going to want to find the right software for your needs. Some of the preferred software tools include Dassault Systemes, Procore Construction Software, Viewpoint Construction, and Hexagon PPM Operational Twin.

- Design the ideal digital model: It all starts with the perfect digital model of the building before any actual construction. No building can be created without the most basic of plans, and no digital twin building can be made without a robust digital twin recorded in the necessary computer models. This may take some additional work compared with the computer models that you’re used to, but the power of a digital twin building plan is unparalleled.

- Set up digital twin data collection tools: Digital twin data during the construction process can be implemented by any number of smart tools, such as smartphones, cameras, Internet of Things devices, etc. These tools will need to collect the data to compare with the digital twin model and keep it updated for all the construction project’s digital twin needs.

- Compare data during the process: The digital twin power will only be fully unlocked when the data is analyzed and use during the construction process, so this will need to be focused on by one person or team to continue to utilize the output intelligence from the digital twin model.

Roadblocks for Digital Twin

While digital twin technologies can open a lot of doors for the construction process, it is, of course, not without a set of hurdles. For example, the technology is still new, and there are a lot of learning curves associated with using it that make its implementation a costly endeavor. While those costs will likely be worth it in the end, a construction project with a limited budget might have to make tough decisions on whether or not to use it. Additionally, digital twin technology is still relatively nascent for the construction industry, meaning it requires a good amount of time and expertise for implementation. Securing the resources needed is not always straight forward, and could require bringing in outside expertise. Lastly, the real possibilities of digital twin technologies may not be fully understood and appreciated by everyone during the course of the construction process. It’s important, for digital twin buildings to be truly powerful, for educational initiatives to be run so all can take advantage and truly optimize the power of digital twin technology in the building sector.

IndiaCADworks Can be Your Digital Twin Partner

Digital twins are already there for you to tap into and make your building smarter, your planning more efficient, and construction more effective. IndiaCADworks (ICW) is an expert on all digital planning and construction technologies, and we offer a wide range of services that cater to the architectural, engineering, and construction industries. With close to two decades of experience, ICW has watched the AEC industry going digital and has stayed abreast of all the latest and greatest tools to make that happen. We are ready and able to make clients in the real estate, entrepreneurship, and construction industries smarter using advanced software and technologies, including digital twin. Apart from architectural engineering, civil engineering, and advanced structural engineering services, reach out to us for a free consultation on how digital twin can revolutionize your construction projects.

-India CAD works