To What Extent Could 3D Printing Be Used In The Food Industry?

When 3D printing first burst onto the scene, it was the realm of high-tech engineers who were creating production models, rapid prototypes, and critical machining tools. However, a lot has changed in the 3D printing world over the past decade, including 3D printers becoming cheaper, smaller, and thus more accessible.

Another exciting development has been updated on what sort of output could come from 3D printers, thanks to new materials being viable to create the 3D models. 3d printing in the food industry is a great example of some innovative and exciting new practices in the world of 3D printing. Don’t believe it? Keep reading to learn more.

What is food 3D printing?

The natural first question to ask is: what exactly is food 3D printing? Well, it’s exactly what it sounds like, and it builds upon the additive and automated ways to build products and models using plastics or metals in traditional 3D printing. The difference, of course, is that instead of plastic or metal, the additive material used is food-based and edible.

By feeding a computer-designed outline of the food into a 3D printer for food, you can create an infinite number of new creations. For example, a 3D printed pizza can be generated by having a dough base built line-by-line until it’s the exact desired shape (whether that’s a circle or something more creative) and then using a 3D printer to also apply precise amounts of tomato sauces in the exact quantity and location it’s desired. Pizza is just one example, but your imagination only limits the possibilities.

Benefits of edible 3D printing

As with early form 3D printers, the next natural question after ‘what’ is ‘why.’ Why exactly would someone want their food 3D printer—wouldn’t that be more expensive and complicated in the end? Well, that may have been the case at first, but the truth is studies have shown several undeniable and viable benefits of 3d printing in the food industry:

- Product differentiation & innovation The first benefit to the foodservice industry can’t be denied: having edible 3d printing in front of customers is just a cool experience that will likely draw in new customers away from competitors because it’s different and new.

- Customization Beyond that ‘cool’ factor, though, 3D printing actually would allow foodservice purveyors to offer more options for and an easier process to customize. By having customers select exactly what they want and in what quantity and in what location on a digital display, that customization can be completed with 100% accuracy and much-enhanced speed compared with traditional human employees.

- Direct-to-consumer relationships Building on that idea, food 3D printing also empowers direct-to-consumer relationships for the ordering of food products outside of the restaurant. Customers can figure out exactly what they want, order it from an online food retailer with 3D food printing, and trust that relationship every time moving forward.

- Reliability of product With all of the above and any other food services using additive 3D printing, having a customer know that the computer will produce exactly what they asked is much more reliable than they’ve ever had before.

- Speed of delivery Further, to achieve that guaranteed accuracy, a regular cook would need to use up more of his treasured time that is so rare, but with edible 3d printing, the high levels of customization can be delivered upon with great speed.

When breaking down the question of benefits, making food with a 3D printer opens up a host of new options that haven’t yet been mentioned. While, of course, 3D food printing would enable the creation of personalized, precise, and reproducible food with ease and with exactitude, creative chefs (both professional chefs and home chefs) would be empowered by 3D foot printers to go even further.

For one, the ability to use 3D food products would open up new, unusual, and nutritionally valid food compositions that would break up the monotony and introduce new flavors and essential vitamins to people’s diets. For people who might need a specific amount of a given nutrient (for a diet, because they have diabetes, or because they are on some medicine), this capability opens up a whole new world. And for people who want to introduce new types of food products to people’s diets, 3D printing opens up a world there.

3D Printing in Food Industry Today

3D printing your food may sound like it’s way to futuristic to be viable today, but numerous applications can and do get used in the food industry today.

- Creating items from pureed food Because the additive process needs to have food that can be ‘squeezed’ out and stay where they are, the easiest method to deliver upon that is to create items from pureed versions of food. The Foodini is a commercially available 3D food printer that does this already today, and it can be used to create items like ravioli, pizza, burgers, and even cookies.

- Creating sugar candies, cake decorations, and centerpieces In the world of elaborate and fancy baking, the decorations often matter just as much, if not more, than the taste of the product themselves. Countless television shows demonstrate the great opportunities for complex cake decorations, but also the high skill and steady hand that’s required to accomplish these. Well, with food 3D printers, such as the ChefJet, edible sweet decorations can be printed out today and added directly to your cake. Elaborate sugar models, precise and accurate cake decorations, and more can come from these good grade printers to elevate the decorations on even the least decoration trained bakers.

- Creating Chocolates Staying in the realm of sweets, chocolate printers are commercially available for bakers and hobbyists as well. The chocolate is commercially available and can produce chocolate products (whether for decoration or direct consumption) in intricate patterns, exactly to specification, and all with great accuracy and ease.

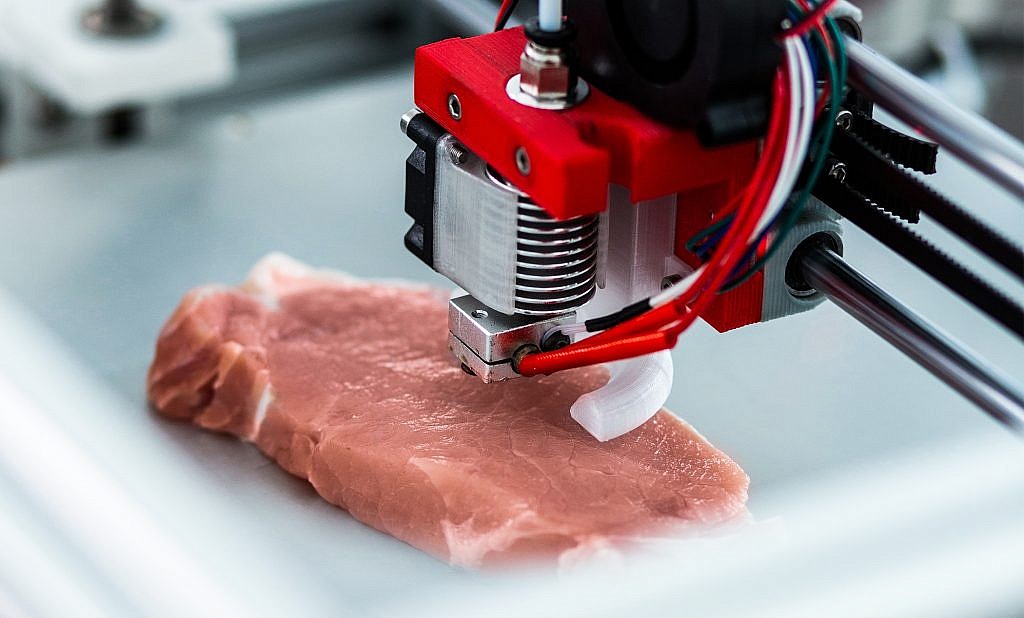

- Printing Meat A more futuristic look into 3D printing in the food industry comes from the potential to print living organic cells to create meat, all without having to kill animals. By using stem cells and growing tissue, meat products can theoretically be printed with these cells as the additive part building up to final edible tissues and cuts of what is identical to meat but grown outside of animals.

The NASA 3D Printed Food Project

Just like 3D printers went through immense development to identify and make possible the applications that the printers could revolutionize, 3D footprinting is currently in the process of going from niche application and neat gadget to something that could change the world. Specifically, NASA and other space agencies are looking at the possibility of using 3D food printing as a means to create fresher food in space.

The current food preservation system is flawed and can’t adequately keep Earth-born food on a trip to Mars, but the NASA 3D printed food project is looking at ways to use 3D footprinting to take powdered proteins, carbs, and other nutrients and be able to print out what the astronauts need in their diets in a form that is edible, desirable, and will keep those in space happy, healthy, and well-fed.

The BeeHex Pizza Printer

Another area to watch with 3D food printing is the BeeHex Pizza Printer, which reportedly can print an edible pizza in just one minute, only needing five more minutes to cook said pizza fully. This type of product could be the beginning of a common household appliance that can prepare and cook food products in kitchens across the world.

For now, though, having this type of automatic pizza printer and cooker would have immediate application and audience in theme parks, shopping malls, sports arenas, and elsewhere.

Conclusion

Often, it does feel like we’re living in the future. 3d modeling made that the case in engineering and manufacturing with the ability for rapid prototyping, creating parts you needed to be custom made, and more. But food 3d printing in the food industry is now making all of that seem old fashioned, and the ability to reshape the food industry is on the table. Whether it’s making food more nutritious, more accessible, or more appealing, the possibilities are endless.

– IndiaCADworks