Will Online Software-Assisted 3D Printing Become The Way Of The Future?

3D printing online has become very popular within the CAD-driven community as well as in the non-technical community.

While many people look at 3D printing as a strictly recently breakthrough, the technology has existed since the late 20th century. Charles “Chuck” Hull invented stereolithography, the basic technique behind modern 3D printing, all the way back in 1984. For many years, though, this technology was unknown to the masses, thanks to secretive patents and the lack of information-sharing. However, over the past few decades or so, 3D printing has become pervasive and available.

The reduced prices of 3D printers and 3D printing software, the improvement in 3D printing materials, and the increased attention to 3D modeling and design before any prototyping in the industry has created a perfect storm where 3D printing is finally accessible, robust, and essential.

Previously, the market for 3D printers belonged to 3D Systems® and Stratasys®, who are the undisputed leaders in 3D printing technology. Although high-end 3D printing is still controlled by these leaders, a new market has arisen in which hobbyists, tinkerers, and small business owners have no difficulty in printing objects such as toys, cups, shoes, and many other shapes at home.

The two key reasons why 3D printing has become commonplace are not difficult to determine. They are:

- There are many good quality 3D printers that cost less than $2000 and are within the affordable price range of small businesses. There are also low-cost 3D printers between $150 and $300, which are well within the affordable price range of hobbyists and tinkerers.

- The cost of 3D printing software has been declining rapidly, and much free online 3D printing software has become available.

How Accessible Is 3D Printing Software to The Average User?

When computers were first invented in the 1970s, took up entire laboratories at Universities until the technology progressed to the point that computers now fit on our desks, in our backpacks, and even in our pockets. 3D printing equipment had followed a similar trajectory, at first only being accessible and reasonable at large research institutions before technology progressed in a way that reduced the size, the cost, and the hurdles to access. These days, 3D printing is more accessible to the average user than ever before.

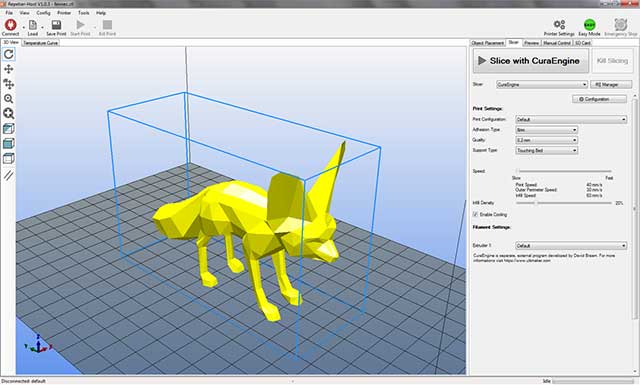

Users can download 3D printing software, they can 3D print online, and the accessibility of 3D printing for beginners has never been greater:

- FreeCAD This 3D modeling software allows you to use parametric 3D designs to create real-life objects that can then be exported to 3D printers. FreeCAD is accessible to beginners and inexpensive to download.

- AccuTrans 3D When using AccuTrans 3D, you’ll be able to take 3D models in other file formats from other software tools and fine-tune them with textures, material properties, and more before you send them to the 3D printing equipment.

- 3D Transform 3D Transform is a 3D modeling software popular among web designers with a low barrier of entry knowledge-wise before you’re off and creating useful models to send to the 3D printer.

- i3DConverter This software is another that will take 3D models of many different file formats and get them ready for the 3D printer. Even better, there’s a free trial, and the lifetime license only costs $50, making it accessible to most average users.

- Blender Blender represents software accessibility via it’s free and open-source nature, allowing anyone access to play around with creating 3D models that can be utilized with 3D printing.

- MeshMixer When you don’t want to spend immense amounts of time learning and getting up to speed with 3D printing software, MeshMixer is a great option for its ability to create and edit 3D models in just minutes, all designed with an eye towards 3D printing.

- Materialise Cloud Materialise Cloud takes customization to the next level by allowing users to create and use custom tools to enhance the 3D process, providing another means of access to 3D printing to the masses.

- Selva3d For users who have little to no background in 3D modeling, Selva3d is unique in its ability to upload photos or logos and create from that a 3D model intuitively in a way that immediately makes printing those designs easy and readily available to the average user.

Benefits of 3D Printed Tools

Another reason for the slow start to the 3D printing industry was because the use cases where 3D printing would be leveraged were niche and not widely understood. However, as computer software improved and manufacturers began to invest heavily in 3D modeling in the design process, 3D printing thus became a natural extension that allowed anyone with access to a 3D printer to create a relatively low-cost prototype, physical mold or model, or even critical machine part.

This transformation in attitude and application from 3D printing has come from the bevy of invaluable benefits of 3D printing tools, which include the following:

Create Sophisticated Models

Previous physical models used in architecture, machining, manufacturing, or any other industry were cruder out of necessity. Creating a scale model presented challenges to be accurate, representative, and complex, but with the aid of 3D modeling and 3D printing software, any models on the computer can now be easily transformed into sophisticated physical models you can hold and touch thanks to the precision of 3D printers.

Fast, Efficient Development

The physical models of old created by engineers and architects in years past were also extremely cumbersome and time-consuming to create. Taking physical materials and creating a model that lined up with the designer’s vision took many iterations, long and frustrating nights, and were overall inefficient. 3D modeling and the ability to print those 3D models, however, turned that wasteful process into a fast and efficient one that can be done in an automated manner in a fraction of the time.

Complex Designs to Order

Because of the increased speed, automation, and complexity offered by 3D printing tools, companies can now offer customers and clients to ability to create intricate and previously unthinkable models to be designed and customized based on their specifications. Complex machine parts can be printed, models that build onto each other into large and complex structures (even building up to homes!), and even 3D printed tools are all able to print to order.

Utilize 250 Materials

An often-overlooked benefit to 3D printing is that modern 3D printing tools can utilize hundreds of different materials in the model to reflect whatever a given design needs, including metals, plastics, rubber, food products, and even organic materials like leather or stem cells.

100 Times Faster

While 3D printing software and equipment is massively improved over past years, researchers are continually making improvements that make 3D printing an even more accessible and on-demand task, including a recent development that can get printing rates up to 100 times faster than was previously considered standard. This means projects that used to take overnight can now be completed in a matter of hours, even minutes!

90 Percent Material Efficient

One of the important factors of 3D printing in the early days came to the materials costs, as the 3D printing materials were expensive, and worse much of the material had to be cut away and discarded at the end of the process as the model was punched out. However, recent developments in the additive manufacturing process have greatly reduced the amount of material wasted in the 3D printing process, allowing for more affordable and environmentally friendly 3D printing.

Which Types of Objects is Being Printed with 3D Technology?

Believe it or not, it is possible to print just about any object with a 3D printer, provided that a template exists for the object. Here is a list of objects, which even hobbyists and tinkerers have printed (or could print), and the list is just a tip of the iceberg.

- A 3D acoustic guitar was printed in plastic, complete with the metal sound whole cover, and heel joint.

- A template for printing a working firearm is available, and functional firearms have been printed.

- A Shakuhachi Japanese flute was printed out of stainless steel.

- Various types of figurines were printed as decorative furniture pieces.

- iPhone cases and iPad stands, coffee cups, shoes.

At a more serious and higher commercial level, here is a partial list of objects being printed with 3D technology:

- Medical models of human body parts are becoming an integral part of the tools required for medical instruction.

- Local Motors® demonstrated at the 2014 SEMA Show in Las Vegas that it can print an electric car named Strati.

- BAE Systems® announced that certain components of British fighter jets were made with 3D printers.

- Prosthetic limbs for amputees are being made with 3D printers.

- Dental restorations are being made with 3D printers, with software provided by Stratasys®.

- Chocolate, pizza, ravioli, and other types of food are being made with 3D printers.

As mentioned earlier, just about any object can be made with a 3D printer, provided that a template exists for the object. With CAD technology, the creation of templates will become easier with time.

4 Big Advancements to Anticipate in 3D Printing (2019-2024)

Even given all the progress in 3D printing during the past decade that has made the technology more accessible to the average user, the next five years should provide some more significant breakthroughs that will change the world of 3D printing, especially for average users.

The technological limitations on 3D printing speed have tended to be the force a printhead can withstand, the speed at which material can be heated, and how quickly the printhead can physically move. However, engineers and scientists have continued to break down these barriers and increase world record speeds by focusing on ways to improve each of those slowdowns.

One of the industries taking the greatest advantage of 3D printing is construction and the ability to build a home from 3D printed materials and parts. Not only does the prospect of neighborhoods filled with 3D printed homes brings with it reduced costs and time constraints, but the materials used in such homes are less and create homes with a more sustainable footprint on the environment.

While 3D printing was forged on the back of plastics, the future of 3D printing will come in metals. 3D printed metals will be used in jewelry, car and airplane parts, machine parts, and more. This is the next step for the 3D printing industry.

While voice assistants like Siri and Alexa can turn your lights on or play you music by calling them to action, 3D printing will enable a (not too distant) future where you can ask for a new pair of shoes to be printed, a custom piece of food to be printed, or a replacement part for your furniture that broke, all by saying “Hey Cogni, design me…” whatever you want! Combining 3D printing with artificial intelligence and customization will truly unlock the next generation of 3D printing.

Conclusion

3D printing software has undergone immense advances in recent years but in terms of what will be possible from 3D printers and associated software the future is even brighter. By embracing the future and the advancing technological landscape, 3D printing is going to undoubtedly revolutionize nearly every industry imaginable. Don’t get left behind, get in touch with IndiaCADworks today to see how we can integrate 3D printing into your operations today.

– IndiaCADworks