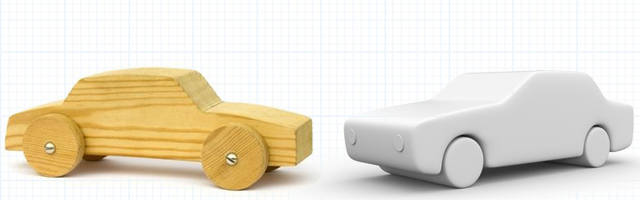

Rapid prototyping is a cost-effective way to show a basic end product while reducing your risk on innovation projects. It’s the process of quickly mocking up key components of a system or physical part and validating it with users, customers, and stakeholders helping to bring the final product to market faster. Rapid Prototyping and innovati

Archive for the ‘ Mechanical ’ Category

Today’s engineer lives and thrives in a 3D CAD model world. CAD models provide design versatility and a direct link to rapid prototype development. As a result, our libraries of CAD models are ever more important. Reverse engineering using 3D scan data is a fast and efficient way to generate CAD models when an object exhibits a complex shape or when a 3D model does

CAD and CAM are industrial computer applications, which have greatly reduced the time and cost cycles between initial concepts and product development. They have enabled designers and manufacturers to make significant cost savings. These tools also reduce the time to market for new products, and reduce the number of design flaws, which tend to hamper productivity, and

The use of 3D modeling over the past 20 years has greatly improved the ability of engineers to design, model, and fabricate complex parts for a variety of industries, including automotive, aerospace, and biomedical, just to name a few. Imagine a tool that would help civil engineers, city planners, and construction crews plan out networks for their water distribution a

Proof-of-Principle (PoP) Prototypes are a cornerstone of engineering design. PoP, also referred to as Proof-of-Concept, prototyping is an effective way to rapidly take ideas from intangible designs to tangible, working models. Developing these prototypes enables you as an inventor or designer to demonstrate the fundamental technology used in your product to be fabrica

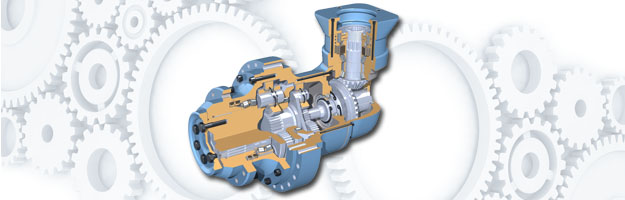

The use of Computer Aided Design (CAD), Finite Element Analysis (FEA), and Computational Fluid Dynamics (CFD) for Engineering Design Optimization provides tremendous added value to the product design process. The use of these tools is a major factor in reducing design costs by allowing numerous simulations to be performed using computer software in the time that it wo