Is the Gap Closing between CAD Design and Manufacturing?

Computer Aided Design (CAD) focuses on using computer software to create engineering and architectural designs which include mechanical, electrical, building, and many other types of designs. Computer Aided Manufacturing (CAM) focuses on using computers and robotic systems to assist and guide the manufacturing process. The term CAD CAM has been coined to describe the synergistic workings of CAD and CAM systems to create an integrated system.

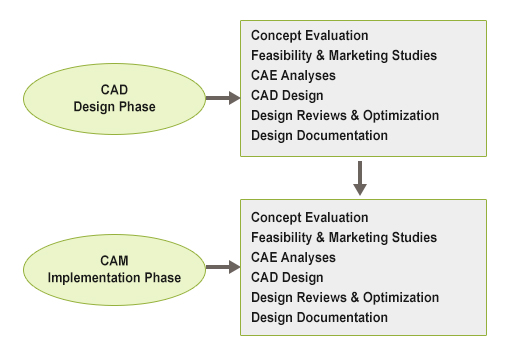

Although CAD CAM systems are expected to integrate the steps of a typical product life cycle, the steps involved in a typical product life cycle are still demarcated by two distinct phases: the design and implementation phases. These two phases can be described by the simplified diagram shown below.

This article addresses improvements that are being made (or which need to be made) in the CAD CAM industry in order to close the gap between CAD design and CAM manufacturing. Currently, a well-known integration between CAD and CAM is called Industry Foundation Classes (IFC). IFC is an industry-wide standard file format for exchanging data between different CAD systems. BIM (Building Information Modeling) serves as a good example for implementing IFC as a multi-disciplinary and collaborative process.

Efforts directed towards improving integration between CAD and CAM could be clarified by answering these questions:

- Which steps in the current CAD CAM cycle could be improved?

- What improvements are being made at this time?

- What improvements lie on the horizon?

Which Steps in the Current CAD CAM Cycle Could Be Improved?

Computerized steps in the CAD CAM cycle which integrate CAD and CAM are referred to as CIM (Computer Integrated Manufacturing). The good news is that CIM is already being implemented by leading CAD companies, and improvements in CIM are ongoing.

The basic functions of CIM are:

- To provide efficient and effective transmission of design information between CAD and CAM systems. One area of improvement is to have lossless data conversions between CAD file formats, and between CAD and CAM data formats. As more data formats adopt an object oriented approach, data conversions will become more efficient.

- To maintain libraries of standard components in order to make reuse of previously designed components possible.

- To provide for design reviews and verifications against specifications and established standards.

- To facilitate design modifications in ways which minimize delays in the manufacturing and production process.

- To maintain synergy between electrical, mechanical and architectural design teams before the manufacturing phase begins.

- To integrate all important activities which are relevant to the CAD CAM cycle. This includes tooling, material ordering, quality control, packaging, marketing, shipping, and other activities which are related to the production process.

What Improvements Are Being Made At This Time?

Although there is no known CIM which has been adopted on an industry-wide basis, there are examples of well-coordinated and integrated CAD CAM production systems that deserve mention:

- When Boeing® produced the 757 airplane, the company introduced many CAM procedures into the CAD design phase. As a result, Boeing benefited tremendously in the post-design or manufacturing phase of the project. For example, assembly of the fuselage and wing spars took 2 days instead of 10 days, and Boeing saved over 30% of person hours in the assembly process.

- Cannondale® used concurrent engineering (a form of CIM) to integrate all production and design systems into a single database that was accessible to all professionals involved in the design and production process. As a result, Cannondale increased production within a year by a factor of 5.

- Autodesk® created IFC Open Source Export for Revit in 2011. Autodesk’s Revit products provide both IFC file export and import.

- SolidWorks® has supported IFC since 2009 for both export and import. Models created using SolidWorks can be integrated within other CAD data files such as Autodesk’s Revit or ArchiCAD.

What Improvements Lie On The Horizon?

Because of certain significant technological achievements within the past decade, it is reasonable to expect these improvements in CAD CAM integration:

- The cost of computing has decreased. One reason why CIM succeeded was that the cost of personal computers and CAD workstations decreased significantly in the last two decades. Because cloud computing is being rapidly adopted, there should be another noticeable improvement in CAD CAM integration.

- Many companies have reported on the benefits they gained from CAD CAM integration. Because of this, there could be a shift toward adopting an industry-wide CAD CAM integration system. Some companies are already enjoying the benefits of CIM, although on a proprietary basis. Rather than trying to protect their design and manufacturing processes as trade or industrial secrets, there could be a shift toward adopting an industry-wide CAD CAM integration system. Industrial secrets do not last forever, because they are often disseminated through industrial and academic publications.

- Increasing use of robotics will improve the manufacturing process by minimizing or eliminating human errors, and by making it possible to perform manufacturing, assembly, and production work in environments that may be hazardous for humans.

- The application of 3D printing will replace many manufacturing processes, especially those which require mold designs.

- CAD voice control, if successfully implemented, will improve productivity.

Conclusions

It is probable that future releases of CAD software will conform to IFC standards in similar fashion to what BIM does. This would make CAD designers pay more attention to how a specific design interacts with other related designs, and how a specific design fits into the integrated manufacturing and production plan.

As more companies publish the benefits that they gained by conforming to an integrated CAD CAM system, their competitors will follow suit, and the chances of CIM attaining an industry-wide standard will improve.

The main enablers for improving CAD CAM integration in the near future will be cloud computing, robotics and 3D printing.

– India CAD works