Reverse Engineering Services

A prominent leader in diverse reverse engineering techniques, IndiaCADworks (ICW) offers unwavering support for new engineering product development projects worldwide, including in the U.S., Canada, Australia, and Europe. Our project teams deliver comprehensive reverse engineering services, catering to needs such as part customization, out-of-production replacement parts, casting molds, and beyond. Leveraging adept drafters and cutting-edge software packages, ICW produces a range of deliverables, including 3D models, 2D drawings, part technical details, and other drafting services, enabling an integrated engineering package.

-

Need a Custom Quote?

- Contact Form

- Live Chat

- info@indiacadworks.com

- 855-259-3709

Reverse Engineering Services from IndiaCADworks

Our skilled project team members are subject matter experts in their fields and also have experience across a variety of disciplines such as – design validation and optimization, finite element analysis, and value engineering, etc. This versatile workforce allows us to support any industry in their reverse engineering requirements. We support manufacturing operations through rapid prototyping, 3D printing, and similar techniques. We focus on prosthetics, orthotics, and custom devices in the medical field. We also serve industries like aerospace, automotive, foundry, and mining. Our expertise covers a broad spectrum of services, including:

- Part Scanning: Utilizing 3D scanning technologies, we can take the whole product or product parts and recreate engineering design drawings. By utilizing technologies like Portable and Fixed, CMM, 3D Laser, and CGI, our engineers replicate the parts as the first step of the reverse engineering services process.

- Computer Aided Inspection (CAI) and Computer Aided Verification (CAV): After reverse engineering a product, our team will use CAI/CAV that serves as the final proof of work that the recreated piece aligns with the original. Utilizing 3D scanning technology, CAI and CAV can detect any difference between the recreated part and the computer design or original part.

- Benchmarking: A reverse engineering use case can be to determine a product's strengths and weaknesses, and then benchmarking can be used to identify upgrades that will optimize the final product. Our team will take reverse engineering services to the next step by benchmarking ways to improve the new product.

- Detailed Part Specifications: Our team will go further than just creating 3D drawings of relevant parts, we’ll identify where those parts line up with existing commercially available or producible pieces. By identifying exact specifications, such as nut and bolt measurements, you can identify the exact way to create a product.

- Drawing and Modeling Packages: Our teams involved in reverse engineering services are highly trained on the relevant drawing and modeling software and related modeling and drafting packages, meaning we can create all the technical drawings you’ll need during your reverse engineering project.

- Parametric Modeling: In the process of reverse engineering services, a parametric model can, in the form of a 3D model, capture the design intent of a product, thus allowing predictions for how a product will be impacted over its lifetime. Our team will create the ideal 3D model but can also implement parametric modeling to add value to the design optimization.

- Hybrid Surface Modeling: Our project teams utilize hybrid modeling, or the process of using references from scans and combining those with perfected and idealized geometry of products, thus improving accuracy and factoring in intent while minimizing the time and resources required for each model.

- Shrinkwrap Surface Modeling: Our team uses Shrinkwrap modeling that is using a collection of scanned surfaces to build a product representation, which reduces the amount of data required by models due to inner complexities. Our team also implements this practice to reduce resources you don’t want to waste.

Your Experience with IndiaCADworks’ Process

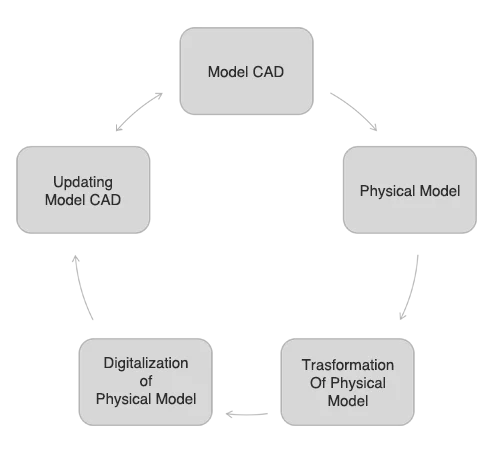

Click Here for Prototyping Process Map

Click Here for Prototyping Process Map

Our team of professionals is proficient in delivering the highest quality services tailored just for you. Our process outline for reverse engineering looks as below:

- We evaluate the specifications, requirement documents, and scope of work received from the client.

- After the engineering feasibility study, we send the concept design samples for the client’s review.

- Adhering to the initial scope of requirements and additional inputs from the client regarding the concept design, our engineering team develops the 3D design model. We deliver the final 3D model of the product for prototyping and production with the required specifications.

-

Need Pricing Details?

- Contact Form

- Live Chat

- info@indiacadworks.com

- 855-259-3709

Benefits of Availing the Reverse Engineering Service from IndiaCADworks

When you make the decision to utilize the reverse engineering services from IndiaCADworks, you get not only highly trained professionals completing your work at an accelerated schedule, for an affordable price, with unmatched quality, but you’ll also be privy to numerous technical end benefits.

- Identify ways to make products cheaper: Our reverse engineering processes will let you identify weaknesses and areas where the money is being wasted in the current production process, allowing you to replicate the product but at a lower price.

- Replicate one of a kind parts: When coming across unique parts, reverse engineering can be the only way to identify how to recreate that piece. Our expert teams will guide you on such replications.

- Analyze a competitor’s product: Reverse engineering is critical for examining, analyzing, and getting intel on products being put out by your competitors. Through our reverse engineering process, we’ll help you find any flaws, defects, or areas for improvement in your competitor’s product to be used by your company.

- Create engineering drawings for handmade prototypes: Some engineering processes will see a prototype that is hand-made by a designer without engineering drawings but to move forward, you need to be able to recreate that product via CAD. The reverse engineering team at ICW can put our talents to work for that purpose.

- Create a nominal model for inspection purposes: The reverse engineering process can be used to create a nominal and ideal model that can be submitted to investors, inspectors, and engineers for inspection and review.

- Make changes and improvements to a product’s design: You can enlist our reverse engineering teams to review your product’s design and, through our analysis and modeling, identify areas where improvements are possible and changes can lead to optimal design.

- Preserve and document handmade molds & obsolete parts: Often in the world of engineering, you may come across handmade molds, one of a kind parts, or obsolete old parts, none of which have documented engineering drawings. IndiaCADworks can use our reverse engineering expertise to preserve and document these designs.

- Blueprint parts for government certification: When getting government or regulatory certification on any type of product, it’s often imperative to submit blueprints for your parts. If you created them without given blueprints, our reverse engineering services could create these blueprints.

- Create the mold for a part: If a part was handmade or is for any reason one of a kind, it can be useful for you to have a mold created to replicate a masse in the future. Reverse engineering services from ICW allows this to be done.

Contact IndiaCADworks for Your Reverse Engineering Needs

ICW’s reverse engineering services play a vital role in your design process of a complex product part and are necessary while engineering and manufacturing products. Thanks to the deep experience and savviness our team brings across the range of potential software and scanning tools, as well as the advanced equipment we have available, we can deliver precisely what you need with accuracy, timeliness, and affordability that will outdo anyone else on the market.

Please contact us today to ask any questions about our reverse engineering team, determine if our reverse engineering services may be of service to you, and find out more!

-

Start with a Free Trial?

- Contact Form

- Live Chat

- info@indiacadworks.com

- 855-259-3709